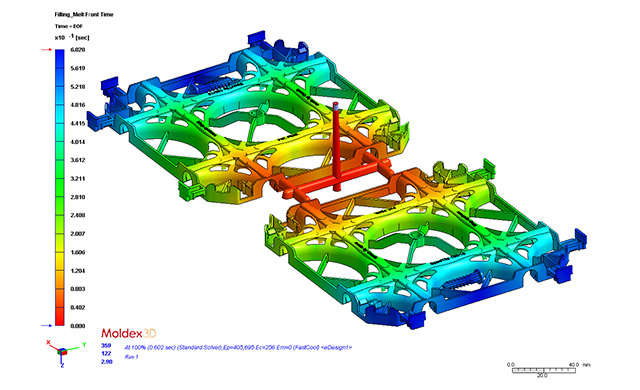

At this stage, we simulate the product and the production process using advanced software, a lot of product knowledge and extensive practical experience. Moulds are very expensive, so it is crucial to know what is possible and where the technical limits are. Simulation gives the customer certainty in advance, but it also helps us: if we are not entirely confident yet, we will not start production.

Parameters like material, thickness, homogeneity, injection pressure, closing force, processing temperature and cooling coefficient are important in simulation. We discuss possible improvements with the customer. Simulation leads to better understanding, smarter solutions and higher delivery reliability.